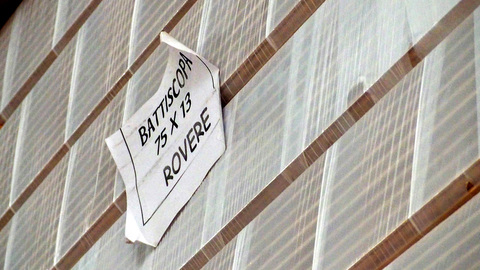

How a skirting board is manufactured

1 Selection of raw materials

Each material is thoroughly examined and tested. Suppliers and raw materials are subject to careful selection and constant monitoring to guarantee quality and reliability.

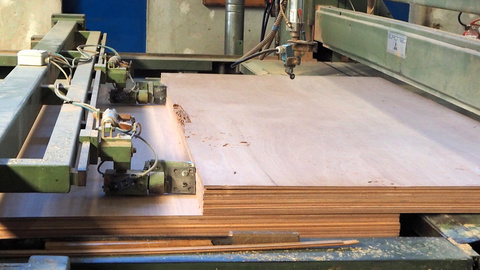

2 Cutting

Supports are cut, optimized and tested so that they match the requirements for the next manufacturing steps.

3 Shaping / Profiling

This step determines the shape and the size of the profile.

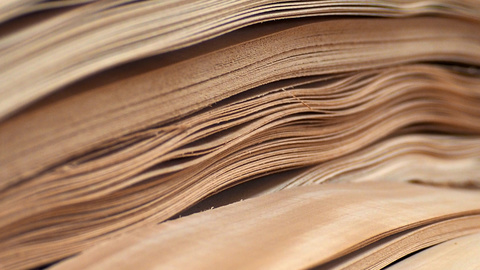

4 Veneering

Maybe the most important manufacturing step, where it is the expertise and experience in applying veneer sheets that makes all the difference.

5 Jointing

Profiles are adjusted in length and joints are created according to the client's specifications.

6 Smoothing

A careful smoothing with abrasive sheets and discs optimally prepares the veneer for the finishing chosen by the client.

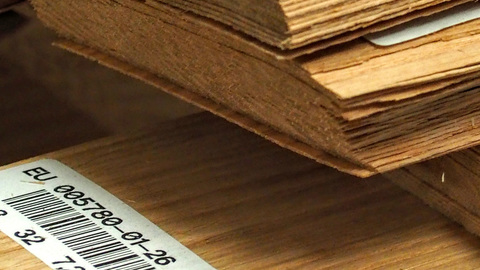

7 Selection / Packaging

The quality control is carried out by experienced specialists and guarantees the aesthetic and structural quality of the product, while the packaging prevents colour alterations of the profile.